Summary

- Yellow mustard bran is a natural thickening and emulsifying agent, a gum substitute and can be used as a bulking or a natural thickening agent and as a gum substitute

- Yellow mustard bran contains about 5.5% mucilage, a soluble polysaccharide, which is responsible for the rheological properties of the bran

- Yellow mustard mucilage (YMM) has shear thinning properties similar to xanthan gum

- Water soluble YMM exhibits good freeze thaw stability when compared to gum Arabic and citrus pectin

Introduction

Brown and Oriental mustard (Brassica juncea) and Yellow (White) mustard (Sinapis alba) are most commonly used as condiments and flavouring agents in North America and Europe. Processed mustards (e.g. ground seeds, flours, meals, and bran) are used as functional ingredients in salad dressings, mayonnaise, sauces, pickles and processed meats. In many regions of Asia, the extracted oil from B. juncea is considered a major edible oil product. Fractionation of the mustard seed into bran (seed coat), protein, oil and carbohydrate components present opportunities to explore the unique properties of each component.

Mustard Composition

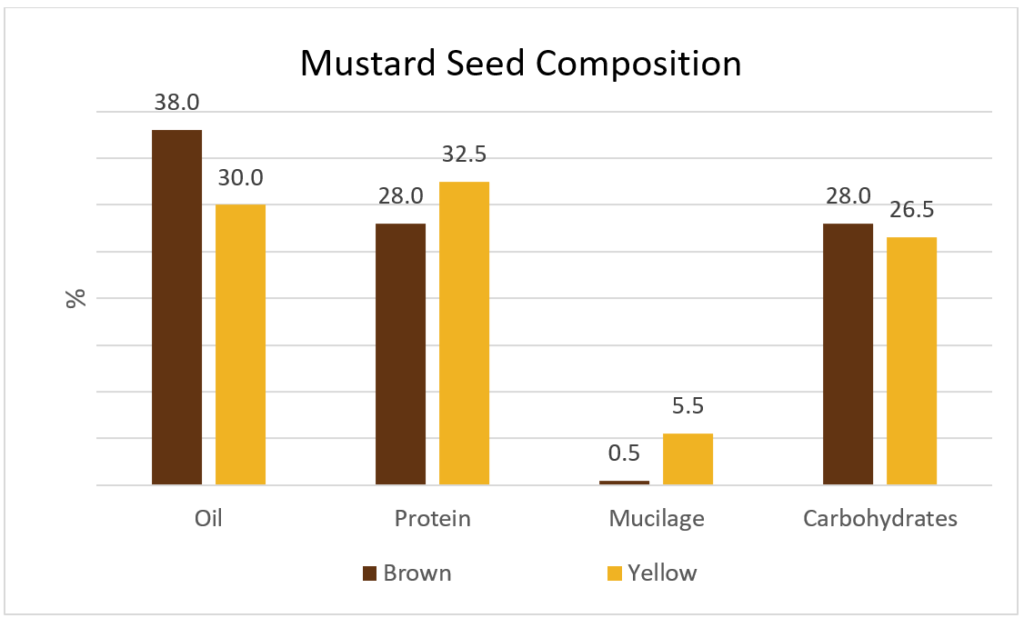

Mustard bran: Condiment mustard seeds are comprised of protein, oil, and carbohydrates and bran (seed coat), which makes up 20% seed as well as minor compounds including minerals (4%), glucosinolates (100-200 μmoles/g), and phytate (2%) (Figure 1). In addition to its value as a flavourful condiment, Yellow mustard seed has long been recognized by industry for its emulsification and water binding capacity in the manufacture of prepared mustards and salad dressings, primarily due to the presence of mucilage in the seed coat.11

Mustard mucilage: About 20% of the Yellow mustard seed composition is the seed coat (bran) which is removed during the dehulling milling process to produce mustard flours. Yellow mustard bran contains about 5.5% mucilage (a soluble polysaccharide) compared to the negligible content in Brown or Oriental mustards. The mucilage is usually found in the epidermal layer of the seed coat and is responsible for the whitish sheen sometimes observed on Yellow mustard seeds. It is the mucilage present in Yellow mustard which contributes to the structure and consistency of prepared mustard products.

While bran, once considered an unusable by-product, today the value of Yellow mustard bran lies in its unique functional properties as a stabilizer and emulsifier, and for its water and fat binding capacity.

Mucilage Extraction and Structure

Mustard bran is first defatted and then the mucilage is extracted via a series of aqueous extractions, centrifugation and precipitation to yield approximately 20-25% mucilage.4,11 Crude mucilage contains primarily carbohydrates with some protein and ash. Through dialysis, the ash content is reduced from 15% to 4.8% with an increase in carbohydrate content from 80% to >90% (Table 1). The carbohydrate fraction is mostly composed of glucose (22-35%), galactose (11-15%), mannose (6.0- 6.4%), rhamnose, (1.6 – 4.0%) arabinose (2.8-3.2%) and xylose (1.8% to 2.0%).5

Table 1. Composition of crude mucilage after dialysis1,3

| Mucilage Composition (Crude, after dialysis) | |

|---|---|

| Carbohydrate | 91.10% |

| Protein | 4.10% |

| Ash | 4.80% |

| Water | 8.70% |

The mucilage is a heterogeneous polysaccharide of a 1,4-linked β-D-glucan (similar backbone to xanthan gum) and a pectic material made up primarily of galactose, mannose, rhamnose, and galacturonic acid.1,2 Yellow mustard mucilage is comprised of water-soluble (WS) and water-insoluble (WI) fractions. The WS fraction is responsible for the rheological properties of Yellow mustard mucilage (YMM) and thus of the bran and whole seed.2

Functional Properties

Yellow mustard mucilage (YMM) is an excellent substitute for replacing other hydrocolloids such as xanthan gum. YMM offers some unique rheological properties in aqueous systems (Table 2) and excellent emulsion capacity and stability in oil/water systems making it commercially viable as a hydrocolloid gum for food and non-food applications. Mustard mucilage has rheological properties similar to xanthan gum exhibiting shear thinning flow behavior, weak-gel properties, and interacting synergistically with galactomannans.

Table 2. Functional properties of Yellow mustard mucilage5,11,12

| Functional Properties | Yellow Mustard Mucilage (YMM) Behaviour |

|---|---|

| Emulsifying capacity and stability | Emulsion capacity and stability of WS-YMM surpassed gum Arabic, pectin, microcrystalline cellulose, xanthan, oat, guar, locust bean gum, carrageenan and gellan. WS mucilage and WI mucilage exhibit greater emulsion capacity, but lesser foam stability than xanthan, guar, and gum Arabic. |

| Surface Tension | Ability to stabilize oil/water emulsions due to interfacial properties which reduce surface tension of water. Up to 0.05% significant reductions in surface tension noted. |

| Viscosity | Salt concentration and pH affect viscosity. Viscosity increases at low or high pH. YMM is effective at increasing the viscosity of solutions at levels as low as 0.5%. Viscosity of solutions decreases as temperature increases. |

| Gel structure | YMM forms a weak gel structure. |

| Shear thinning behavior | Behavior of YMM resembles that of xanthan gum. At low concentrations (0.3%), with a high stirring rate, viscosity of an aqueous solution is reduced, but at low stirring rates, viscosity increases. This quality permits products to be spread, pumped, or poured. |

| Synergistic behavior with other hydrocolloids | YMM acts synergistically with galactomannans (locust bean gum, guar gum) to form gels. Small amounts of locust bean gum enhance emulsion stability, viscosity and gel formation of YMM. |

| Freeze-thaw stability | WS Yellow mustard mucilage exhibits good freeze thaw stability when compared to gum Arabic and citrus pectin. |

Yellow Mustard Mucilage/Bran Opportunities

Current Products

Yellow mustard powder (milled, defatted seeds) is commonly used by the food industry in condiment mustard preparations and sauces. Yellow mustard bran, once just an unused by-product of the milling industry, is now a much sought-after ingredient for its functional properties. Mustard bran is used as a bulking agent, a natural thickening agent and as a gum substitute.

The research on YMM properties has shown that commercial Yellow mustard powders can be mixed with hydrocolloids to enhance food properties. For instance, a combination of Yellow mustard powder with locust bean gum in chicken meat emulsions significantly enhanced the gel strength of meat after processing.5

Yellow Mustard Mucilage as a Food Hydrocolloid

Future applications of isolated YMM lie with its regulatory approval as a pure hydrocolloid to compete with or complement other food hydrocolloids (e.g. guar gum, xanthan gum, locust bean gum) and starches.

New applications and further exploration for food and other uses include the following:

- As a replacement for xanthan gum in formulations

- To produce synergistic interactions with other hydrocolloids

- As a stabilizer for oil/water emulsions and processed meat products

- In frozen food products due to its freeze-thaw stability

- In applications to modify starch properties such as gelatinization and retrogradation, pasting and thermal properties, swelling power and solubility, gel structure and the prevention of syneresis of starch gels7,8

- Antioxidant properties of water soluble Yellow mustard mucilage with possible applications in food products for food quality, product shelf life and replacement of synthetic antioxidants12

Potential Health Benefits of Yellow Mustard Mucilage

- Modulation of the post prandial glycaemic response by mustard bran and YMM9,10

- Potent anti-cancer effect of YMM in animal models for colon cancer6

- As a dietary soluble and insoluble fibre

Yellow Mustard Mucilage Non-Food Applications

Potential non-food applications include use in the cosmetic industry as an emollient, film former, skin conditioner and viscosity control agents for aqueous systems. Products applications include anti-aging formulations, creams, lotions, liquid soap, self-tanning solutions and sunscreen formulations.

References

- Cui, W., Eskin, N.A.M., and Biliaderis, C.G. 1993. Food Chem. 46:169-176

- Cui, W., Eskin, N.A.M., and Biliaderis, C.G. 1993. Polym. 29:215-225

- Cui, W. and Eskin, N.A.M. 1999 In: Functional Foods: Biochemical and Processing Aspects (ED) G. Mazza. Technomic Publishing Co., Inc. Lancaster, PA Pg. 235-264

- Cui, W., Eskin, N.A.M., Han, N.F., Duan, Z.Z. and Zhang, X.Y. 2003. Canadian Patent CA 2270750

- Cui, W., Eskin, N.A.M., Wu, Y. and Ding, S. 2006. Colloid Interface Sci. 128-130:249-256

- Eskin, N.A.M., Raju, J., and Bird, R.P. 2007. Phytomed. 14:479-485

- H., Eskin, N.M.A and S.W. Cui. 2003. Food Hydrocolloids 17:863-869

- Liu, H. et al., 2006. Food Chem. 95:83-93

- Kay, B.A. 2016. MSc Thesis, University of Guelph, January 2016. Accessed May 2016 http://atrium.lib.uoguelph.ca:8080/xmlui/bitstream/handle/10214/9479/Kay_Brittney_201601_MSc.pdf?sequence=1&isAllowed=y

- Lett, A.M., Thondre, P.S. and Rosenthal, A. 2013. J. Food Sci. Nutr. 64:140-146

- Weber, F.E., Taillie, S.A. and Stauffer, K.R. 1974. Food Sci. 39:461-466

- Wu Y., Eskin, N.A.M and Cui, W. and Pokharel, B. 2015. Food Hydrocolloids 47:191-196 Wu, Y., Hui,D., Eskin, N.A.M. and Cui, S.W. 2016. Int. J. Biol.Macromol. 91:710-715